Mighty Armory's Guide to Primer Pocket Swaging

Key Highlights

- Swaging is an essential process for reforming primer pockets during the reloading process

- Primer pocket swage tools are essential for removing crimps from military brass prior to priming cases

- To create a uniform primer pocket, Mighty Armory recommends using a primer pocket swager for both crimped military brass and commercial brass

- Swaging, rather than reaming, is a more efficient and effective process for reforming the primer pocket

- Mighty Armory offers a universal primer pocket swage set that will both decap and swage your cases. The set includes two .078 decapping pins.

- Mighty Armory swage set will save you time and frustration

- The Mighty Armory swage kit is will convert your decapping die to a hold down die for swaging

Introduction - What is Primer Pocket Swaging

The process of reloading is filled with intricate steps, requiring a blend of technical knowledge and practical skills, each contributing to the final product’s performance and reliability. Such steps include: decapping the case, cleaning the brass (order varies depending on the conditions of your brass), swaging the primer pocket of commercial or military brass, sizing the case and loading.

When reloading brass with or without crimped primer pockets, primer pocket swaging is an essential step. Primer pocket swaging is the process of reshaping the primer pocket or removing the crimp from the primer pocket of a spent brass casing, which allows for smooth and consistent primer insertion.

Many brass brands designed for military and law enforcement applications feature a crimped primer pocket to secure the primer in place. Crimped primer pockets can hinder proper seating of a new primer during reloading. For example, 9mm Luger, .40 S&W, .45 ACP, .223 Rem (5.56 NATO), .308 Win (7.62 NATO), .30-06 Springfield, or older European cartridge types like 6.5x55 will typically contain a crimped primer. Although using a swager to remove crimps from military brass, we also recommend swaging commercial brass to uniform the primer pockets in order to achieve consistency when seating primers.

Using a primer pocket swage tool can and should be a simple, quick and reliable way to prepare your brass for loading. Mighty Armory offers multiple options for your primer pocket swage needs.

Why Swaging Matters for Reliable Primer Seating

Case preparation is the foundation of a great round. Swaging primer pockets is essential for creating a uniform pocket radius where a primer will be pressed in.

Proper primer seating affects consistency, accuracy and reliability of your reloads. Swaging ensures uniform primer pockets, reducing the risk of misfires and improving overall performance while shooting.

Swager tools are available as standalone tools or as a reloading bench top mounted swage tool. Mighty Armory offers multiple case hold down die designs for specific types of reloading presses. Each of Mighty Armory's case hold down dies can also function as decapping dies, by simply swapping the hold down tip for a decapping pin.

Finidng the Right Tool for Your Reloading Press

Whether you own an autoprogressive press, an autodrive press, single stage press or Turret press, Mighty Armory has the reloading die to meet your need.

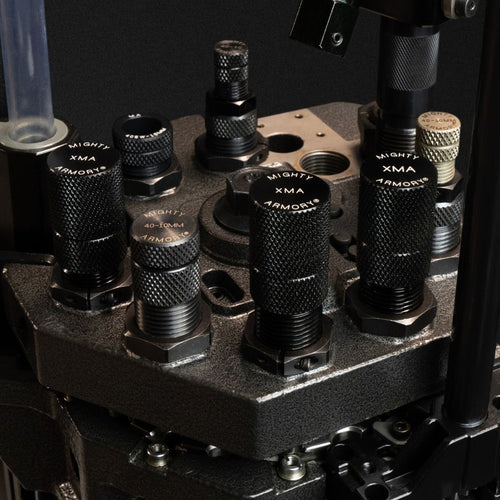

Many autoprogressive presses offer both swaging and priming stations on the toolhead that require a case hold down die over them to achieve proper swaging and primer seating. For this scenario, we recommend either the XMA Hold Down Die, the XMS Hold Down Die or the Super Duty Hold Down Die.

On the other hand, if you operate a single stage or Turret press, your best options is to use the Mighty Armory Swage Set. The Mighty Armory primer pocket swage set includes a hold down die, a universal cup extractor and either a large or small primer pocket swager depending on your need. The swager simply slides into the press ram in place of the shell holder.

On the other hand, if you operate a single stage or Turret press, your best options is to use the Mighty Armory Swage Set. The Mighty Armory primer pocket swage set includes a hold down die, a universal cup extractor and either a large or small primer pocket swager depending on your need. The swager simply slides into the press ram in place of the shell holder.

A unique feature about the Mighty Armory swage set is that the hold down die included can also be used as a decapping die by simply swapping the hold down tip for a decapping pin on the end of the rod. We designed the reloading die this way to make the reloading process easier and more efficient. You only need one reloading die for both decapping and swaging your cases.

Primer Pocket Swaging vs Reaming

There’s two primary ways to prepare the case primer pocket before priming, which are Swaging or Reaming. We much prefer swaging, and here are the reasons:

The process of reaming a primer pocket uses a reaming tool to prep the primer pocket. Reaming removes brass from the case head creating brass filings. It tends to be a longer and tedious process and results in hand fatigue and finger pain during the case preparation process.

On the flipside, there are multiple benefits to swaging. Using a swage tool to reform the primer pocket is a much faster process and results in more consistent primer pockets. The primer pocket radius is reformed rather than filed so no brass will be removed, and there’s no wear and tear on the hands and fingers.

Swaging may also result in a more uniform primer pocket and inside diameter, which will ultimately result in proper primer tension, which is not possible to achieve after reaming.

Mighty Armory's Modular Case Hold Down Dies

The case hold down die is a tool used while swaging. Mighty Armory’s Hold Down Die has a drop-in shaft with a case web (floor) tip that is shaped to hold both small and large primer pockets with authority and not mar the case.

The Case Hold Down Die will mate with the web of the case so the swage can be pushed into the pocket. Set up is quick and easy and the swaging process is very fast.

Mighty Armory Case Hold Down Dies can be used as a static hold down die or dynamic hold down die. The hold down dies with fixed hold down shafts are static operation, and spring assisted hold down shafts are a dynamic hold down. Either will work well with our larger and small swagers depending on your reloading press.

In addition, Mighty Armory’s Case Hold Down Dies are modular designs. This simply means that the case hold down tip that screws into the hold down shaft / rod can be swapped with a decapping pin. The same die can be used for hold down or for decapping operation, depending on your need.

Mighty Armory Primer Pocket Swager Kits & Sets - What's the Difference?

Mighty Armory's primer pocket swage set includes the decapping / hold down die, universal case extractor and swage (either small or large).

The primer pocket swage kit includes the swage tools without the die. The swage kit is available with either the large or small swager, depending on the cartridge you are reloading. If you already own the Mighty Armory decapping or hold down die, then the primer pocket swage kit is an excellent choice to add to your reloading bench.

Our swage tools are designed for use on single stage and turret presses. The Case Hold Down dies are also designed to work on autoprogressive presses swage stations and priming stations with or without autodrives, such as the Frankford Arsenal X-10 Autoprogressive press or the Mark 7 Apex 10 with an autodrive.

The Mighty Armory swaging tools allow you to switch between large and small primer pocket swaging without having to make any adjustments to the case hold down die on the press toolhead. Simply swap the swager tool depending on the primer pocket size you are swaging.

Small primer pockets are generally found on cases such as .223 Rem / 5.56 NATO, 9mm Luger, .40 S&W, and .45 ACP.

Large primer pockets are generally found on cases such as .308 Win / 7.62x51mm NATO, .45 ACP, and .30-06 Springfield.

Photo: Swaged case before (left) & after (right)

Conclusion

The intricate processes of using case hold down dies and swaging play pivotal roles in the realm of reloading. The case hold down die secures the case during the reloading process and ensures precision and consistency, which are vital for the performance of your reloads. On the other hand, swaging, particularly primer pocket swaging, is a critical step that ensure the primer fits securely, thereby enhancing the reliability.

Understanding these processes and their significance can greatly improve one’s reloading skills and the quality of the final product. As we continue to explore and innovate in this field, these techniques will undoubtedly evolve, offering even greater precision and efficiency in reloading. Invest in quality swaging tools like Mighty Armory’s offerings for consistent primer seating, better accuracy and more enjoyable reloading and shooting experiences. Happy Reloading!