Must-Have Reloading Components for the Competitive Shooter

Key Highlights

- Competitive shooters require specific reloading components to ensure consistent and accurate rounds.

- Essential components include single stage, turret, and auto-progressive presses, powder measures, resizing dies, flare expander dies, seating dies, and primer pocket tools.

- Decapping dies play a crucial role in brass preparation. Decapping and cleaning brass will guarantee clean primer pockets for primer setting and clean case bores without carbon burn inside the powder chamber of the case.

- Sizing dies are essential for achieving superior accuracy by maintaining proper diameters for SAAMI Spec reloads.

- Flare expander dies serve a crucial role in the reloading sequence by flaring your case for bullet entry and will set your bullet tension for consistent COLs for seating and crimping.

- Bullet seating dies ensure precision and consistency in overall bullet length and concentric alignment.

- Crimp dies impact reload quality by providing proper case mouth tension and projectile release.

Introduction

Reloading is a critical process for competitive shooters. Whether you are a competitive shooter, long-range enthusiast, or an avid hunter, having control over your reloads consistency and accuracy is essential. To achieve this level of precision, it is crucial to invest in the right reloading components, including quality components. These components play a vital role in ensuring that every round you load meets your unique requirements. Reloading components for precision shooting go beyond just the basics like primers, powder, and bullets. They include specialized tools and equipment that help you achieve consistent results with every reload. By using high-quality reloading components, you can take your shooting to the next level and enhance your overall performance. In this blog, we will explore the must-have reloading components for competitive shooters. We will delve into the role of decapping dies, sizing dies, bullet seating dies, flare expander dies, and crimp dies in order to achieve consistent and accurate reloads. By understanding these essential components, you can take control of your reloads and achieve the precision you desire.

Essential Components for Competitive Reloading

To achieve precision in reloading, several essential components are necessary. First and foremost, a high-quality single stage, turret, or auto-progressive press is required. These types of presses allow for precise control over each stage of the reloading process. A reliable powder measure is also crucial to ensure consistent powder charges. Competitive or recreational shooters can utilize SAAMI spec die sets to maintain proper case dimensions and ensure reliable chambering.

The Role of Decapping Dies in Competitive Reloading

Decapping dies play a crucial role in precision reloading by removing spent primers from brass casings. These dies are specifically designed to deprime the cases without resizing them. By removing the spent primer, decapping dies allow for thorough cleaning and inspection of the brass before the reloading process. This step is vital for brass preparation as it ensures that no residue or debris from the previous firing remains in the primer pocket. Clean primer pockets are essential for consistent primer seating depth, which is crucial for competitive shooting.

Achieving Superior Accuracy with Sizing Dies

Sizing dies are an essential component in pistol precision reloading as they help maintain proper case dimensions for optimal diameters prior to flaring, seating, and crimping. Follow the basic steps on brass prep and measure occasionally to ensure consistent dimensions from case to case. Sizing dies are designed to resize the case neck and the inside of the case to precise measurements. Proper sizing also ensures that each round chambers smoothly and reliably. When using sizing dies, it is important to follow the manufacturer's instructions.

Case Flaring and Bullet Tension Sizing

Proper case flaring is a critical step in preparing for bullet seating. Flaring and expanding should prepare the case for two required diameters: First, the flare, to eliminate the possibility of scoring a bullet while seating, and second, the expander, to set the diameter of the case ID to .003 to .004 bullet tension, which ultimately sets up the proper diameters for the crimp die.

The Importance of Precision in Bullet Seating

Bullet seating is a critical step in precision reloading, as it determines the overall length of the completed round and affects bullet consistency. The seating die is responsible for precisely positioning the bullet in the case and applying the correct amount of vertical alignment to achieve the desired depth. Achieving consistent bullet seating is essential for accuracy and consistency in reloading. By using a high-quality seating die, competitive shooters can ensure that each bullet is seated at the same depth, +/- .005, resulting in consistent overall length across all rounds. Proper COL is crucial for maintaining consistent chamber pressures and bullet alignment, which directly impact accuracy. To achieve the desired bullet seating depth, it is important to adjust the seating die properly and use precise measurements. By paying attention to this crucial step, competitive shooters can maximize their reloads accuracy and achieve consistent bullet performance downrange.

Understanding the Impact of Crimp Dies on Shooting Precision

Crimp dies play a significant role in achieving consistent reload quality and shooting precision. These dies are used to apply a crimp to the case mouth, securing the bullet in place and preventing bullet movement during transport or feeding. Proper crimping is particularly important for reloads used in revolvers and semiautomatics, especially when fed out of a tubular magazine, as it prevents bullets from shifting under recoil or in a magazine tube. By using crimp dies, competitive shooters can achieve reliable quality and shooting precision. Properly crimped rounds offer consistent bullet seating, reliable bullet tension, and improved feeding in firearms. Investing in high-quality crimp dies and following proper crimping techniques is essential for precision reloaders looking to maximize their shooting performance.

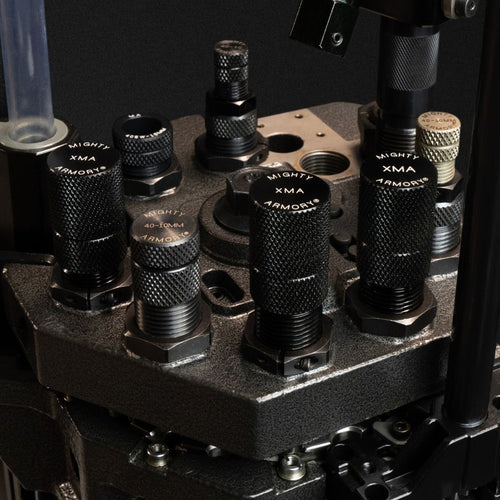

Highlighting Mighty Armory's Precision Tools

Mighty Armory is a renowned brand trusted by competitive shooters around the world for their high-quality precision reloading tools. Their commitment to excellence is evident in the design and performance of their products. Mighty Armory offers a wide range of precision reloading components that are essential for achieving consistent and SAAMI spec, accurate rounds. From decapping dies to sizing dies, flare expander dies, bullet seating dies, and crimp dies, Mighty Armory’s precision tools are designed to meet the needs of the most discerning reloaders. By using Mighty Armory's precision tools, shooters can enhance their reloading process and rely on the quality and consistency of their components adding up to SAAMI spec, similar to what you will find on any major brand offered to the consumer – only better.

Precision Machined Decapping Dies for Consistent Performance

Mighty Armory's precision machined decapping dies are known to be the strongest and most concentric dies in the world. They offer three different decapping die designs, each serving the same job for different reloading presses. Each die offers a primer flicking design to eliminate the possibility of primer pullback. The Magnum and the PUA are designed for single stage and turret presses. The XM series is designed for auto-progressive presses: The XMA for lever presses, the XMS for automated presses. The Super Duty Decapping Die is, as the name suggests, designed specifically for automated presses and offers a drive shut-down sensor that detects bad cases, such as a Berdan case, which will save you time and pin life.

Sizing Dies for Enhanced Accuracy

Mighty Armory's pistol caliber sizing dies are designed to achieve SAAMI spec precision rounds. The full-length sizing bore sizes the entire case above the plate or shell holder. SAAMI spec sizing can only be achieved with a full-length die, similar to sizing a rifle case. It sets the diameters for the other reloading dies in the process. The machine work and polish inside Mighty Armory sizing dies are of exceptional quality. When sizing your brass, Mighty Armory sizing dies provide an effortless experience. The sizing process feels like butter when using the recommended PEG75 (lanolin mixed with 99% alcohol at 7:1 ratio). Their sizing dies are precision machined from high grade tool steel, which ensures durability and longevity; the robust construction needed to withstand the rigors of reloading. Commercial loading companies using Mighty Armory dies have experienced the quality having cycled over a million rounds and they still size to spec.

Set Correct Bullet Tension with Mighty Armory's Flare Expander Dies

Mighty Armory’s flare expander die is dimensioned in harmony with their sizing die. The flare expander will set your case ID for .003 to .004 bullet tension to ensure tight bullet tension. At the same time, the Mighty Armory flare expander die will flare the case mouth so bullet dropping or setting will hold vertically and seat concentrically and smoothly without any bullet droppage and consistent COL. The flare shaft in the Mighty Armory flare expander die is machined from high grade tool steel with a smooth finish to prevent sticking in your case to ensure a seamless flare and expansion process. The finish on Mighty Armory’s flare expander is incredible – they will not stick. Reloaders can rely on these dies for extended use without compromising performance.

Perfect Vertical Alignment with Mighty Armory's Seating Dies

Mighty Armory's innovative seating dies improve concentric alignment and crimps the case mouth approximately 80%, which sets up a quick and easy crimp at proper bullet tension and cartridge overall length. The dies are precision engineered to provide perfect vertical alignment of bullets during the seating process. Mighty Armory seating dies are designed to hold the bullet securely in place while applying the correct amount of pressure to achieve the desired seating depth. By ensuring precise vertical alignment, the dies contribute to improved bullet consistency and accuracy in every reload. The reliable seating of bullets at the same depth across all rounds enhances overall performance and consistency on the shooting range. With Mighty Armory's seating dies, precision shooters can achieve optimal bullet alignment and consistency in their reloads.

Taper Crimp Dies for Optimal Projectile Release (continued)

Tighter neck tension prevents bullet setback and a straight surface angle from the base of the case to the rim around the bullet. You can expect the SAAMI Spec .011 difference from base .388 to the mouth .377.

In Conclusion

Understanding the nuances of decapping, sizing, flare expanding, seating, and taper crimp dies is key to achieving superior accuracy. Mighty Armory sized rounds ensures reliable feeding out of the magazine and a direct pathway into your barrel chamber, maintaining proper alignment and stability. When developing your round, see powder company load data safety measures. For consistent and reliable performance, determine your powder charge and COL. Better than factory loads can easily be achieved using Mighty Armory reloading dies. After load development, you will realize how the rounds stack in the magazine, feed directly out into the chamber, with proper case pressures, cleaner burn, low Standard Deviation, and improved accuracy. The Mighty Armory measured system will take you to your quest for perfection. Example for 9mm pistol:

- Decap the case with ease

- Full length size

- Flare to .380

- Seat to desired COL

- Crimp to .377

Expect improved accuracy and reliability in your reloads. You will see, feel, and shoot the difference. All Mighty Armory pistol dies are tool-free designs, easy set up, easy disassemble, and easy reassemble. Only a 3/16 wrench will be needed to snug the decapping pin. Mighty Armory offers 100% CNC precision machined reloading tools, made in the USA and dedicated to the betterment of the reloading industry, their customers, and their products.

Please contact Mighty Armory with any questions: Email: info@mightyarmory.com

Use Support chat for fastest response.